About Us

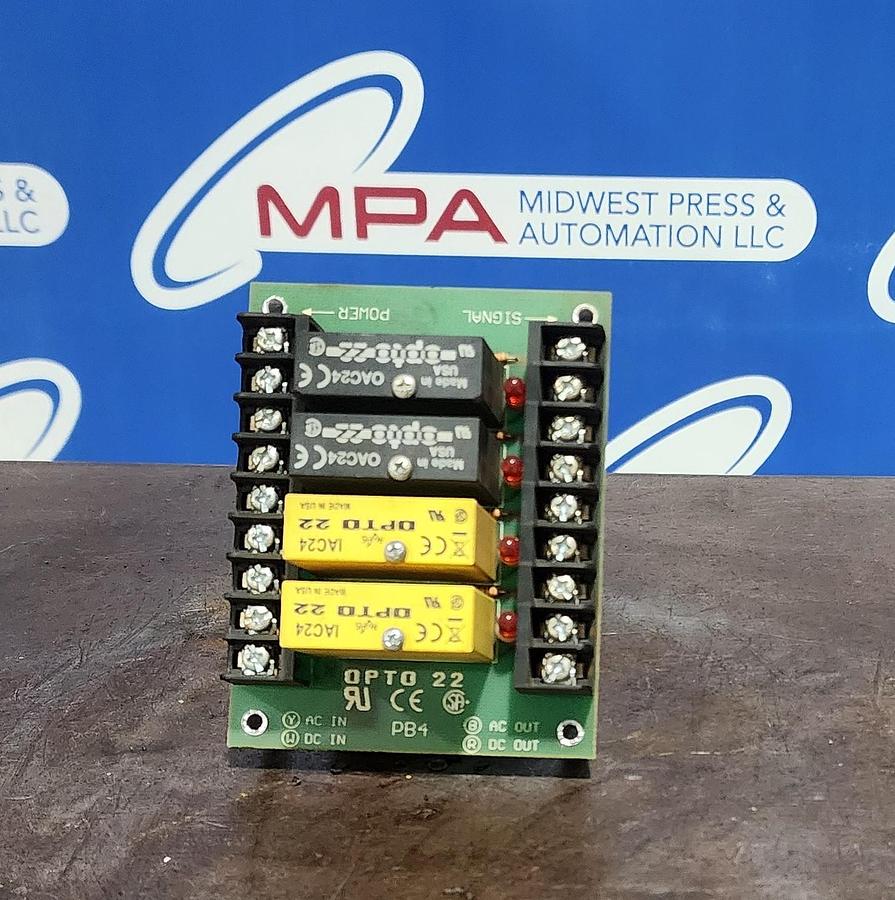

Midwest Press and Automation LLC

A solution-based company serving the Metal Forming Industry.

With over 70 highly qualified employees, MPA has become one of the most diversified companies to serve customers today. MPA strives to keep up to date with the ever improving technologies of the industrial world to keep our customers running in optimal shape. We believe integrity above all things will keep MPA strong for generations to come.

Featured categories

Featured EQUIPMENT

Sign up for our newsletter

Sign up for inventory updates and promotions!

PROUD MEMBERS OF